How to Prevent Wire Harness Terminal Back-Out: Kidisoii’s Expert Solutions

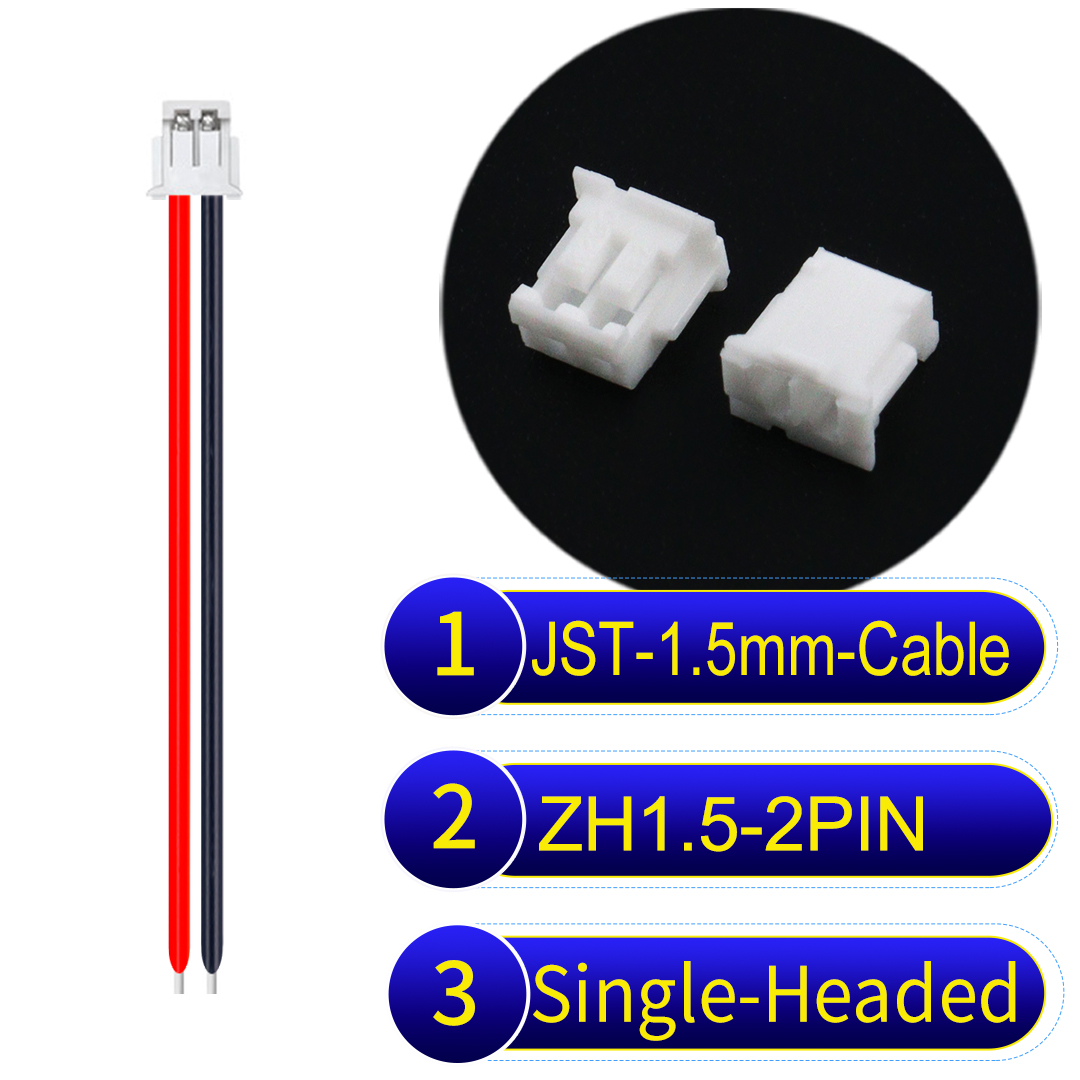

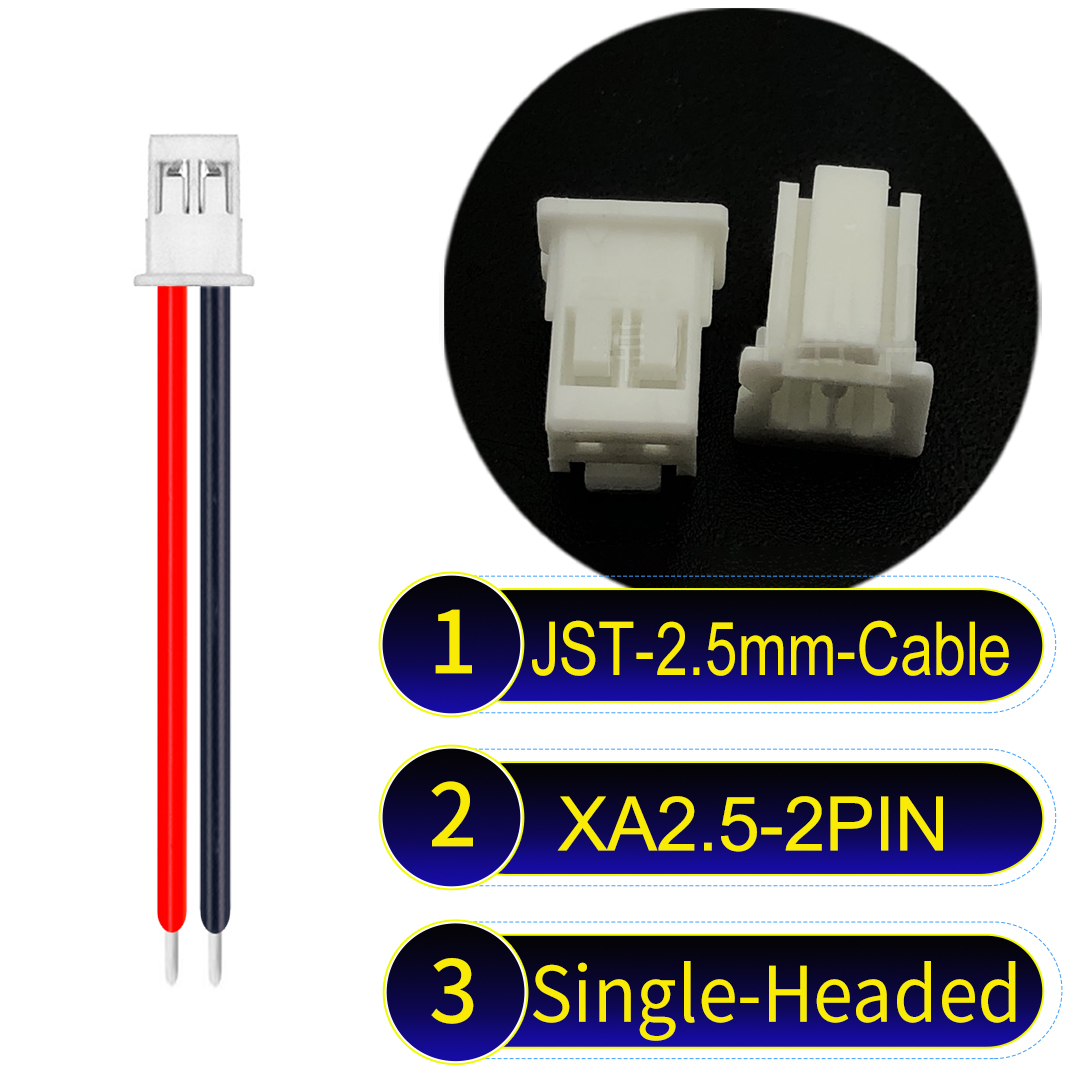

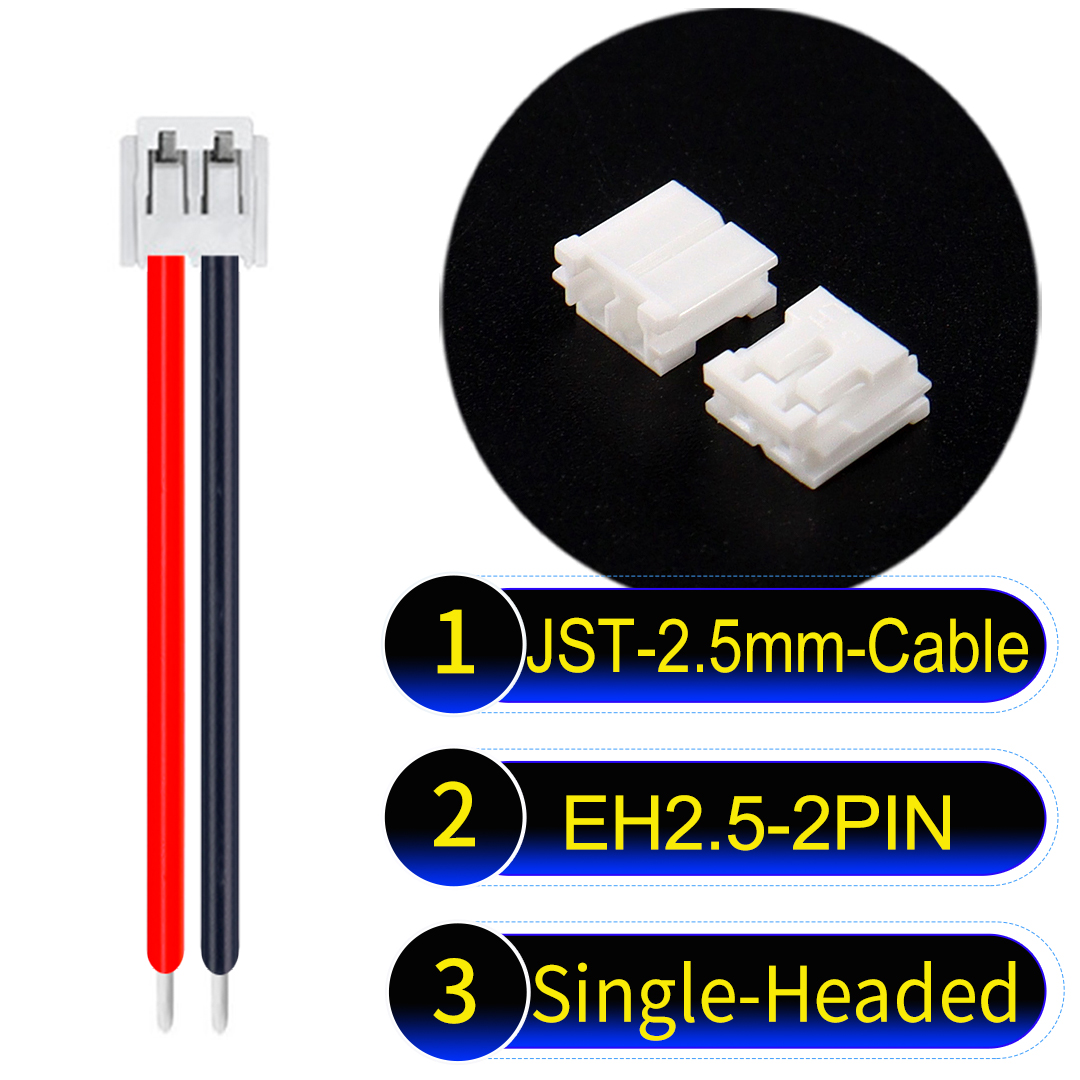

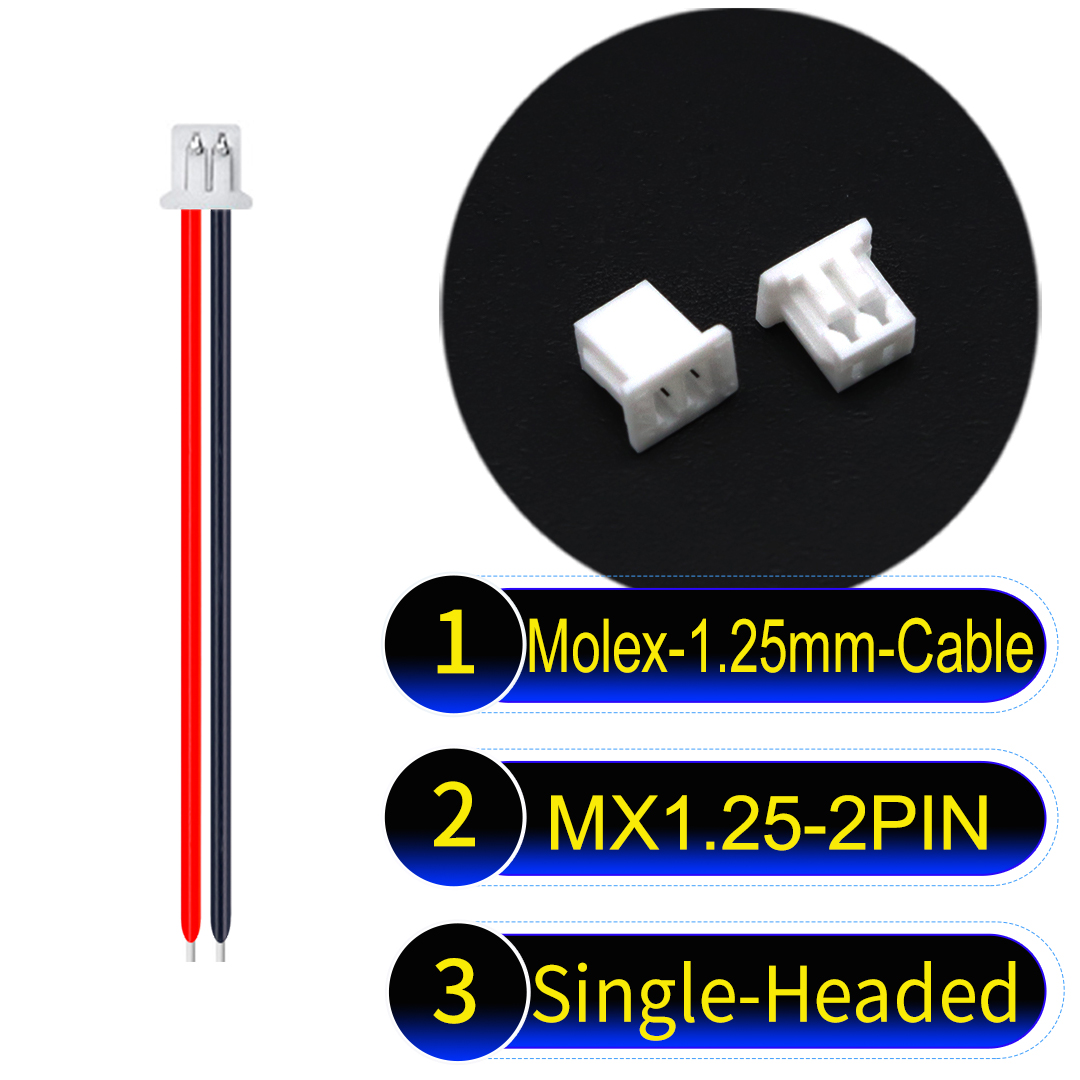

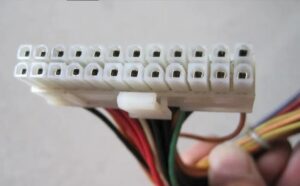

Wire harness terminal back-out can compromise the stability of automotive electrical connections, leading to system failures and increased maintenance costs. At Kidisoii, a professional manufacturer of JST and Molex cables, we focus on providing high-quality, custom-engineered solutions to ensure reliable and durable electrical connections. This article outlines effective strategies across design, material selection, processing, and quality control to prevent terminal back-out issues.

1. Optimizing Terminal Retention in Connectors

(1) Enhanced Structural Design

Connector Housing Elasticity Design

At the product development stage, we use CAD simulation to analyze the deformation of connector latch structures under force. Based on these simulations, we determine the optimal shape, size, and position of the latch to ensure smooth terminal insertion and sufficient retention force after assembly.

To ensure mechanical integrity, we consider the tolerance fit between the terminal and the housing, applying Finite Element Analysis (FEA) to verify that the latch withstands shear stress under extreme conditions. Additionally, we incorporate gradual lead-in surfaces, such as involute profiles, to prevent terminal loosening.

Terminal Elastic Structure Optimization

Using precision CAD modeling, we optimize the thickness, width, and elasticity modulus of the terminal latch to balance assembly ease and yield strength. To account for manufacturing variances, we incorporate fine-tuning structures (e.g., micro-adjusting nuts, elastic washers) that allow on-site adjustments to maintain secure engagement with the housing.

(2) Material Selection and Validation

Connector Housing Materials

We maintain a material database containing specifications for Nylon, PBT, and ABS, ensuring appropriate selection based on environmental and performance requirements. For new product designs, we conduct high-temperature aging tests to measure shear stress limits, adjusting latch dimensions accordingly. If retention force requirements are unmet, we prioritize material upgrades or implement secondary locking structures for enhanced reliability.

Terminal Material Selection

We categorize terminal materials such as copper, brass, and bronze, developing a selection guide to ensure optimal conductivity and durability. Suppliers must provide quality reports, and all incoming materials undergo hardness testing, tensile strength analysis, and batch inspections to maintain quality standards.

2. Addressing Terminal Mating Interference Issues

(1) Structural Optimization

Center Distance Optimization

Using high-precision 3D measurement techniques, we map mating component dimensions and define reasonable tolerance ranges (generally within ±0.1mm, and ±0.05mm for high-precision applications). We employ tolerance analysis software to simulate assembly accuracy and make real-time adjustments if misalignment risks are detected.

Terminal-to-Housing Clearance Design

We apply Design of Experiments (DOE) methodologies to study how fit clearance affects insertion performance. Multiple sample groups are tested for insertion and extraction forces to determine the optimal clearance range (0.05 – 0.2mm). During mold fabrication, we use high-precision machining and maintain strict mold calibration to ensure uniform clearance.

(2) Controlling Terminal Insertion and Extraction Force

Standardizing Insertion and Extraction Forces

Based on electrical performance and assembly process requirements, we establish insertion and extraction force standards:

- Small connectors: 3 – 8N

- High-power connectors: 8 – 15N

Monitoring and Adjusting Insertion Force

Our production lines feature high-precision force testing equipment for sampling and automated analysis. When deviations occur, we trace the production process and optimize terminal processing, plating, and housing molding techniques to maintain force consistency. Regular equipment calibration ensures accuracy.

3. Addressing Assembly and Application Issues

(1) Standardizing Terminal Crimping Processes

Crimping Mold Optimization

Using advanced mold design software and finite element analysis, we simulate crimping stress and strain to optimize die cavity and blade parameters. High-precision equipment and premium materials ensure consistent quality, with extensive trial adjustments before mass production.

Crimping Parameter Control

We maintain a detailed crimping parameter sheet outlining key variables such as pressure and timing. Real-time sensor monitoring ensures consistency, while periodic equipment maintenance and operator training reinforce best practices.

(2) Strengthening Terminal Assembly Management

Standardized Assembly Procedures

A well-documented assembly workflow includes step-by-step guidelines, tool usage, and quality requirements. Operators follow illustrated work instructions, and key quality checkpoints are enforced. Automated inspection systems detect and flag defective products for rework.

Operator Training and Evaluation

We provide structured training programs covering product design, assembly techniques, and quality control. Employees undergo regular assessments, with performance tied to quality KPIs.

4. Establishing a Comprehensive Testing & Quality Control System

(1) Incoming Material Inspection

All terminal and housing materials undergo rigorous batch testing for:

- Chemical composition

- Mechanical properties

- Thermal resistance

- Surface and dimensional quality

Only materials meeting strict quality standards enter production.

(2) In-Process Quality Monitoring

We integrate automated and manual inspections at multiple stages, ensuring early detection of defects. Statistical Process Control (SPC) techniques monitor key parameters, with corrective actions taken when anomalies arise.

(3) Final Product Testing and Reliability Verification

Finished products undergo random sampling and performance tests, including electrical, mechanical, and environmental adaptability assessments. Regular reliability validation tests ensure continuous improvement.

Conclusion

By implementing these systematic solutions, Kidisoii effectively mitigates wire harness terminal back-out issues, enhancing the safety and reliability of automotive electrical systems. Companies can adopt and tailor these strategies to align with evolving market demands and quality standards.

At Kidisoii, we are committed to precision engineering and quality excellence, providing custom JST and Molex cable solutions that meet the highest industry benchmarks. For custom solutions tailored to your project, contact us today!

Why Choose Kidisoii?

✅ Specialized in JST & Molex cables

✅ Custom processing and OEM services

✅ Strict quality control and testing

✅ Advanced engineering and manufacturing expertise

📩 Get in Touch: Visit Kidisoii.com